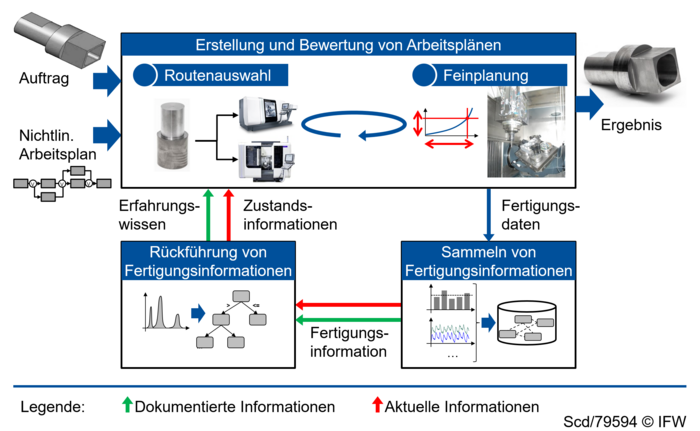

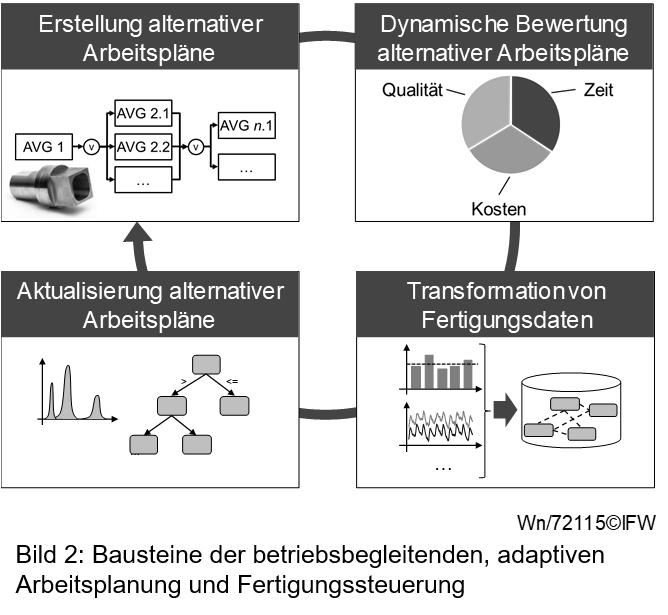

In work planning, static requirements are assumed and optimum production sequences are defined. Dynamic influences (e. g. limited availability of machines) require short-term rescheduling within production control. These are mainly carried out manually by the production planner. In manual rescheduling, alternative production sequences are not systematically evaluated. The consequence is an inefficient planning result. For this reason, a method for integrated work planning and production control was developed within the Collaborative Research Centre (SFB) 653 at Leibniz Universität Hannover, funded by the German Research Foundation (DFG). This comprises the structured collection, evaluation in the virtual planner and feedback of production information as well as the component related definition and adaptation of the production process (see Fig. 1).

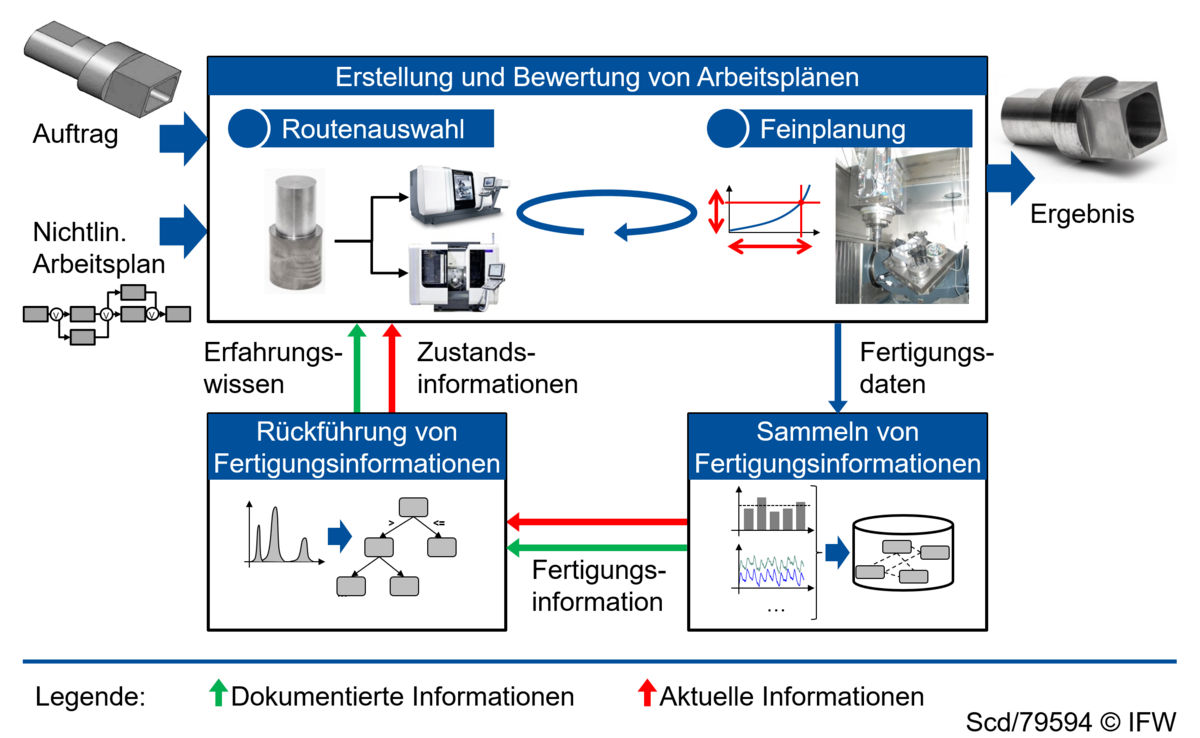

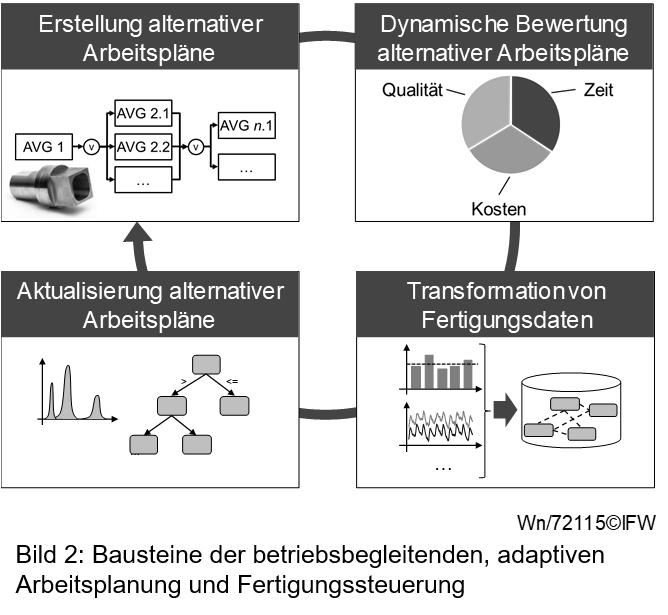

The aim of the transfer project T09 is to transfer the acquired basic knowledge into application. To this end, the method for adaptive work planning and production control will be further developed in an application-oriented manner and transferred to the Fauser MES of Fauser AG and linked to the BDE in Fauser. At the project partner Bornemann Gewindetechnik GmbH & Co. KG, the method is used in practice and is tested and validated in this way. The building blocks of adaptive work planning and production control during operation are illustrated in Fig. 2.

Transferproject leader

30823 Garbsen

Industry partner

30823 Garbsen

30823 Garbsen

31073 Delligsen

31073 Delligsen