Teachless process monitoring for the production of individual parts

Process monitoring of machine tools is an established method used within automated batch production to ensure high process stability and availability. However, process monitoring systems have to be taught reference data during a ramp-up process. In single item production a ramp-up process is not available, thus a teach-in of the process monitoring is not feasible in this case.

The main goal of this research project was to increase process security of production facilities for single item production. Hence, a method for teachless process monitoring was developed, which offers robust and reliable monitoring for production starting with the first manufactured item.

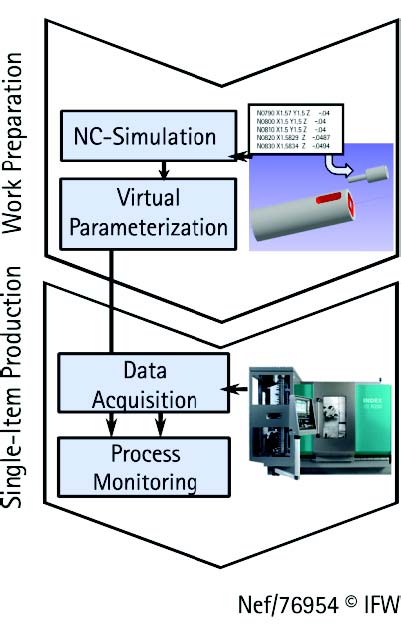

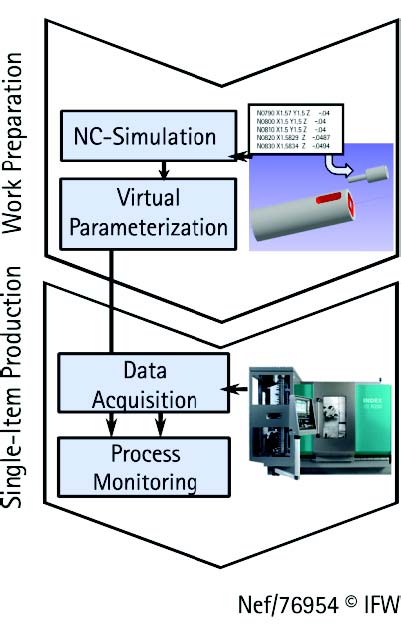

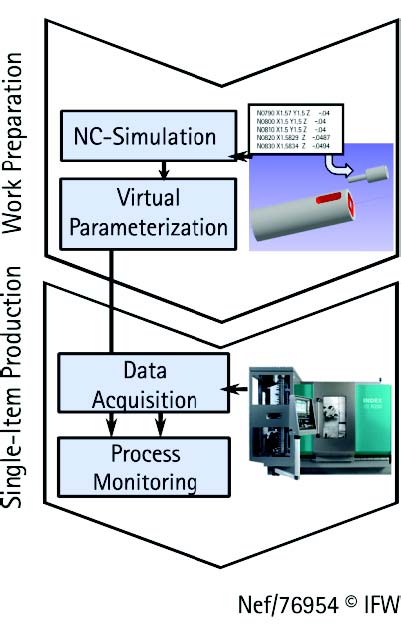

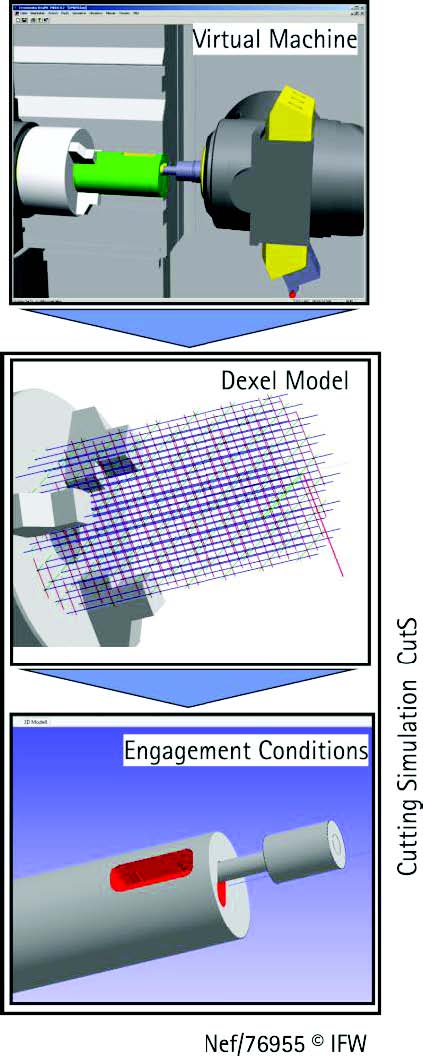

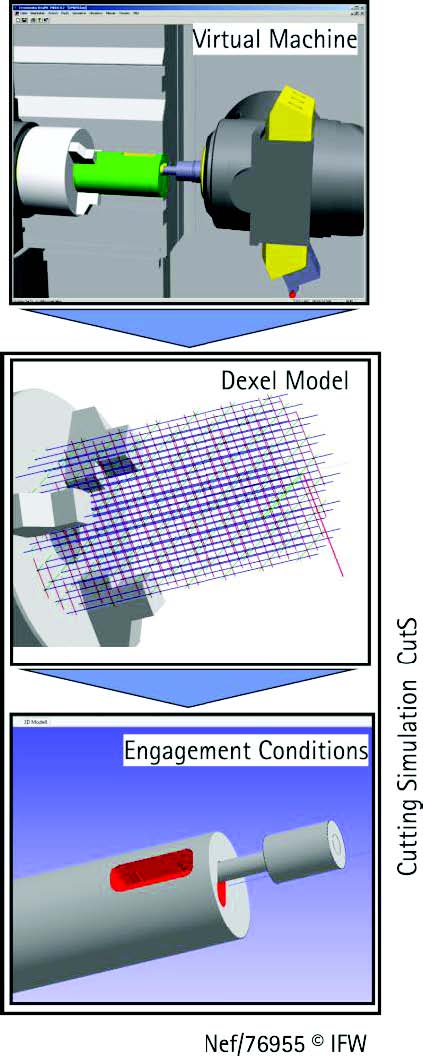

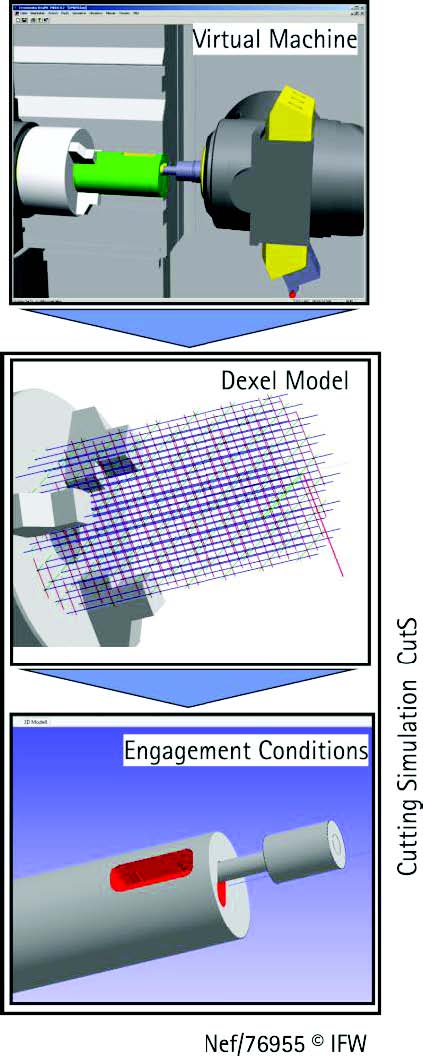

In order to substitute the ramp-up process, a reference for parameterization of monitoring limits was simulated during the process planning phase (figure 1). Relevant information of process planning (CAD/CAM, NCbased simulation) was used to simulate monitoring limits. Hence, teaching of the monitoring system during ramp-up is completely substituted by a simulation during process planning. Thus, an NC-based simulation is not only used to validate and optimize the planned process, which is common practice, but also provides process factors to calibrate the Monitoring limits.

By accessing existing simulation systems to calculate the tool path of a machine tool based on G-code, a way-based simulation of material removal is provided. For calculation of material removal the simulation system “CutS” developed at IFW was used. A tool path based on G-Code was generated by a virtual machine tool of project partner INDEX-Werke. This combined information guarantees a way-based synchrony of simulated reference data and measured signals. The measured signals are provided by a monitoring system developed by project partner ARTIS. The described approach enabled the parameterization of robust monitoring limits parallel to the process.

Focus of this project was to transfer research results accomplished within the SFB 653 into an industrial application. Consequent advancements of these existing approaches lead to a prototype applicable in industrial practice. This prototype enables robust and teachless monitoring of single item production.

Subproject leader

30823 Garbsen

Industry partner

73730 Esslingen

73730 Esslingen

29649 Bispingen-Behringen

29649 Bispingen-Behringen

26316 Varel

26316 Varel