Genetics and intelligence – basics for the implementation of cyber-physical systems and the fourth industrial revolution

Why the world turns cyber-physical - and how gentelligent systems contribute?

The thinking factory and smart products: A world of sensing components and tools which are able to communicate their conditions autonomously. This is the vision of scientists of the Collaborative Research Centre 653 - Gentelligent Components in their Lifecycle. Its realization will have a strong influence on the production of tomorrow.

The Collaborative Research Centre (CRC) 653 “Gentelligent Components in their Lifecycle - Utilization of Inheritable Component Inherent Information in Production Engineering“ seizes the idea of sensitive and communicating products and develops it furthermore. It was in 2005 that the CRC 653 presented ist vision of inherently linked component and Information for the first time: autonomous condition monitoring, determination of remaining lifetime and on demand maintenance of components. Breakdowns due to premature fatigue and costly product recalls, for example in the automotive sector, could thus be avoided. In the subsequent years, the CRC developed prototypes with enhanced functions, such as the detection of loads and inheritable information, which required novel manufacturing technologies and provided new maintenance processes.

In this respect, benchmarks were set in the past, also reflected by the most recent research approaches: With the research initiative “Industry 4.0“ launched in 2012 by the Federal Ministry of Education and Research in cooperation with the Federal Ministry of Economics, the integration of digital information and the corresponding physical components, known as “cyber-physical systems”, found more and more its way into research and industry. By 2020, Germany should be the main provider of cyber-physical systems.

Many approaches of the new research initiatives focus on the use of RFID (Radio Frequency Identification) technologies. The research of the Collaborative Research Centre 653 goes one step further by eliminating the physical separation of component and component-related information. Today, component and component-related information just form a unit in terms of a virtual component, in the early product development phase.

In their lifecycle (production, utilization, recycling), component and component-related information are normally separated physically. The date and history of manufacture, quality data, material, revision state, product models and other information are not directly available any more. To retrieve Information about an individual component, normally the component’s serial number – if available – must be readout, and then access to a locally separate data base is necessary.

Therefore, the main focus of the CRC 653 is on the research and development of novel manufacturing technologies, enabling components to collect Information inherently about themselves and their LifeCycle and store them inherently. The integration of sensory components in complex machines creates an entirely new dimension of condition and process evaluation. Integrated into a system, new opportunities arise for production planning and control which are constantly adaptable during the process.

In 17 interdisciplinary subprojects of the CRC 653, different technologies and applications are investigated and combined and the results are implemented into applications in industry. Besides the Faculty of Mechanical Engineering and the Faculty of Electrical Engineering and Computer Science of Leibniz Universität Hannover, the Laser Centre Hannover e.V. is also affiliated to the CRC.

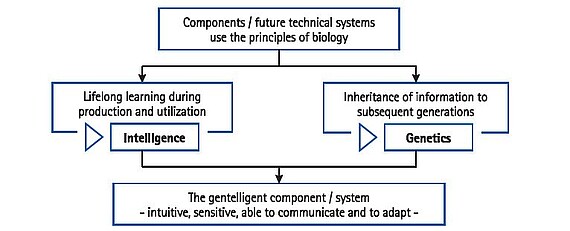

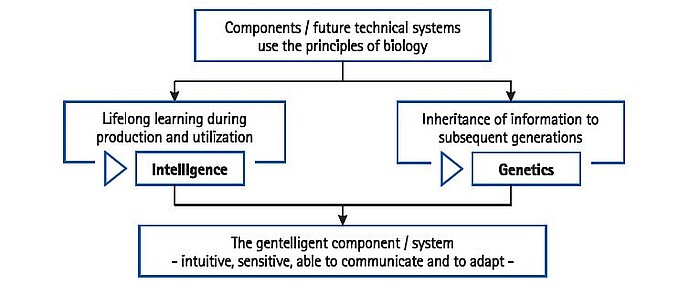

What are gentelligent components?

The term “gentelligent“ is a compound of the words “genetic“ and “intelligent“, describing components with genetically intelligent properties, as in biology. Components are enabled to collect information of their lifecycle, to store and communicate them. This creates the basis for transferring the principles of biology in terms of information inheritance to subsequent component generations and lifelong learning. The CRC 653 calls the utilization of real product LifeCycle information for the product and production evolution “technical inheritance“.

Genetic information of a component is basic Information required to identify or reproduce a component, such as geometrical descriptions or material data. This information is stored in the component as static unchangeable data and can be inherited from a previous component generation. In addition, the component includes manufacturing data which for example may be enhanced by quality data. The intelligence of a gentelligent component is due to its technical ability to inherently and autonomously collect data during the utilization phase, such as forces and temperatures, and to process and store them. This is realized by using appropriate materials and sensors, integrated into the component.

All data stored in the component can be communicated on demand to the user of the component or readout in case the component is disassembled or replaced. The data as a whole is inherently linked to the gentelligent component and recallable at any time. In this way, a gentelligent component is characterized by inherent sensory properties and the ability to store and communicate component-inherent data (Figure 1).

What can be achieved with gentelligent components?

During the manufacturing process as well as in the lifecycle and in the further development of a component, the inherent ability to store knowledge, gain and communicate experiences provides for example:

- distinct product identification and its use as protection against plagiarism,

- specific production and assembly planning and production control,

- identification of failure causes, failure probabilities and remaining lifetime as well as determination of dynamic maintenance intervals,

- design of new components by means of real load profiles, identified during the utilization phase of preceding components.

Results of the Collaborative Research Centre are transferred into practice, promoted by the “Production Innovations Network“ (PIN), a spin-off of the CRC 653.

In the factory of the future, components and machines will be able to communicate with each other and make decisions on their own. The development of gentelligent components, tools and systems is the basis for a networked Industry 4.0 compliant production.