Design optimization by assessing real life load information over a product's life cycle

The focus in the research project is located in the exploration, development and adaptation of methods, tools and processes to support an integrated product development. To generate a high degree of automation this includes elaborations regarding a better performance and efficient process flows. Therefore it’s necessary that the integration of knowledge, such as novel knowledge based engineering (KBE) methods, is realized as well as an increased flexibility within the process chain is created. In context of the enablers of the CRC the product development can be supported by a performed intergenerational process evaluation. This process is called technical inheritance and is defined as:

“Transfer of assembled and verified information from production and application to the next product generation”

In all phases of the product life cycle a huge number of different data are generated, which could be used by a suitable data preparation as information for the development of the next products generation. Through a further development of specification and modeling techniques, the life cycle of various technical systems can be mapped very accurately in terms of information flows. This allows a subsequent analysis for the identification of development-relevant information.

By the consideration of physical, human-related and economic aspects as well as technological trends, product specific hypothesis can be formulated. To gain a feedback of these questions about the products life cycle, existing measurement technology can be used. Further the gentelligent enabler can be integrated in the technical system. Therefore a design catalog is developed to support the engineer in the selection of a suitable technology to realize a monitoring strategy. Concomitantly data mining methods are directly integrated in the stages of development process. The measured data were classified and associated to typical product life cycle situations of the technical system with the goal to reduce the data volume. Through the process of the technical inheritance, product specific information can be generated, which represents a great advantage for the development of the next product generation.

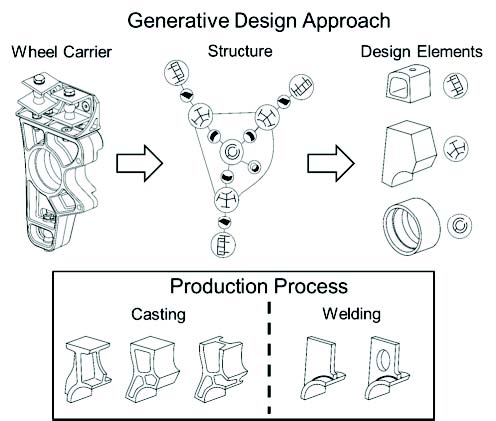

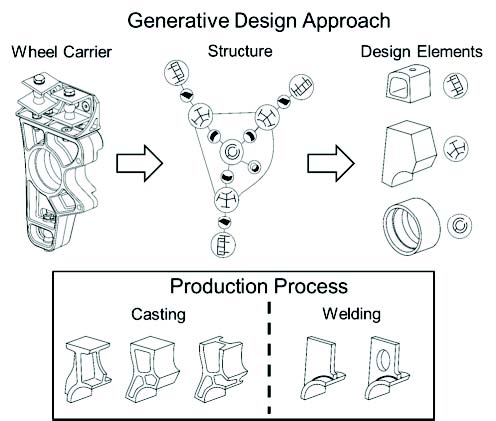

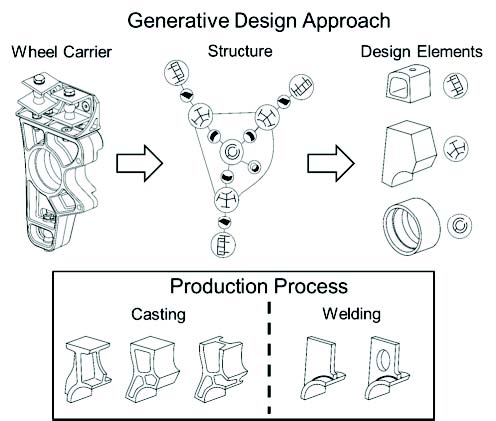

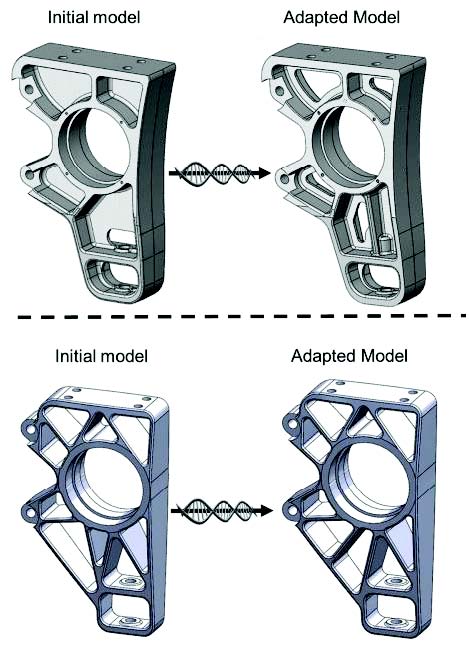

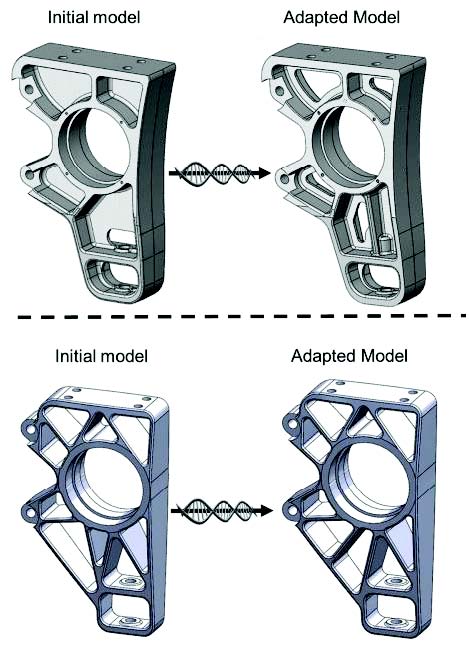

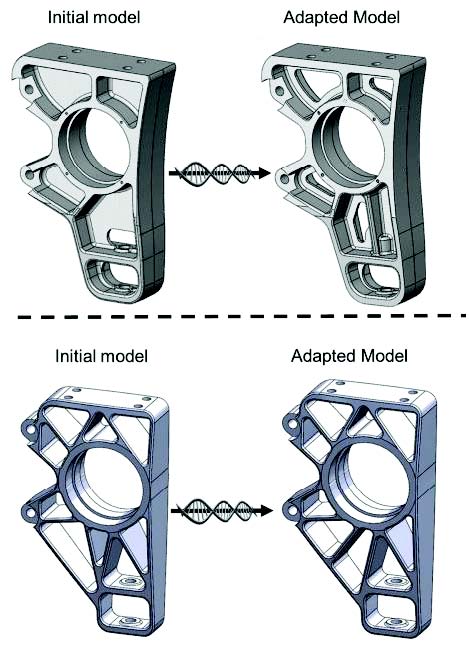

Furthermore, virtual product models are developed within the framework of this subproject that support the integration of usage information in context of KBE. By using these models, an automatic design adaption of the product in dependency of changing during the usage is offered. By focussing mechanical components a generative design approach is developed, depicted in Figure 1. By the coupling of this generative parametric models with simulation environments, optimization strategies for the adaption of the shape can be realized. Therefore, genetic algorithms are applied to adapt the component to optimal design regarding the respective usage information. Like depicted in Figure 2, optimized wheel carriers are based on different usage information is demonstrated.

Subproject leader

30823 Garbsen