Determination of loads by applying magnetic magnesium alloys

The aim of the subproject E2 is the development and production of magnetic magnesium alloys with sensory properties. These alloys can be utilized as load-sensitive materials, because they enable a material-inherent collection of relevant information about the operating conditions, especially the applied dynamic mechanical loads, by the change of their magnetic properties. These changes result from the inverse magnetostrictive effect (Villari effect) and can be read out and processed during the component’s service by utilizing modern methods of non-destructive component testing and material characterization such as high resolution eddy current technology using harmonic analysis. With the aid of such measured loading history data, the resulting fatigue life can be derived so that the maintenance intervals can be planned and subsequent generations of components can be optimized.

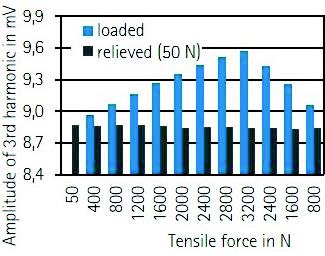

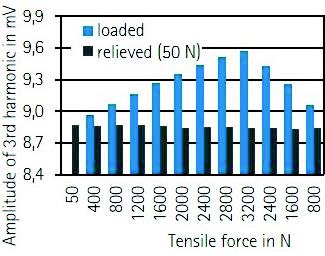

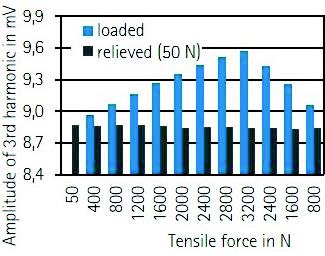

Magnesium alloys have great potential for lightweight construction due to their high specific strength at low density. Since magnesium itself and common Mg alloys do not have ferromagnetic properties, novel alloys based on magnesium and cobalt were developed in the subproject E2 whose microstructures contain phases having explicitly measurable ferromagnetic properties. The magnetic properties of the Mg alloys subject to cyclic loading are determined by means of a harmonic analysis of eddy current signals in cooperation with subproject S3. The harmonics’ measured values provide information about the instantaneous material condition and the lattice distortions as a consequence of the forces acting on the Mg specimens.

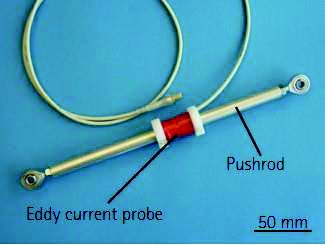

Here, several alloy variants based on magnesium and cobalt exhibit magnetic sensitivity suitable for an online-measurement of the applied loads (Fig. 1). These methods can be employed in order to, for example, monitor the forces exerted on a vehicle’s pushrod (Fig. 2).

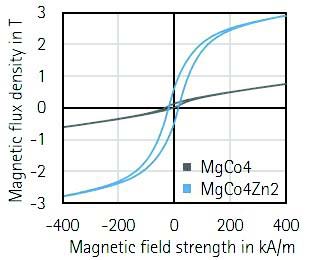

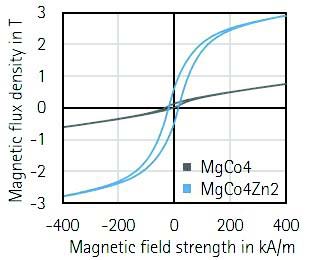

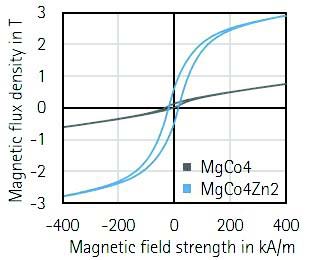

In addition to that, the magnetic Mg alloys enable material-inherent information storage. In Fig. 3, two magnetic hysteresis curves of as-cast alloys are compared.

The aim of subproject E2 in the third funding period is the material-inherent inheritance of information regarding the section of a sensory magnesium component which was overloaded during service. The measured values of the eddy-current testing used to determine the magnetic properties show a permanent increase as a result of high mechanical loads. It will be investigated if it is possible to utilize this behaviour in order to detect a component’s local overloading. In addition, the formation of the magnetic phases during the solidification of magnetic magnesium alloys will be controlled by pre-defined cooling conditions in order to produce magnesium components with locally adapted magnetic properties.

Subproject leader

30823 Garbsen